JEB International is a global leader in partition systems and operable walls – how do they maintain standards and meet client expectations across borders? Timothy Burndred, Global Sales Director for JEB writes.

June 16th, 2016

JEB frequently works with clients who hold a distinct global presence. This is partly due to the emergence of co working spaces on the verge of exponential international growth, coupled with fortune 500 companies updating their global portfolio as the dust settles at last post GFC.

The expectation of JEB’s clientele is high – reflecting the level of the industry on the whole. While working styles, and working spaces vary from industry to industry, and from country to country. Naturally however, client’s expectations on standard and superiority are equally as high anywhere in the world. When considering international and satellite site rollouts – why should quality ever differ in one locale to the next?

The JEB team is skilled in different markets, working with different people from different walks of life, managing vastly different companies and characters who all boast their own unique vision and approach – elements that ultimately bring about their own global success.

For JEB, maintaining standards across various regions comes down to four key factors: product design, tailored or bespoke design, prefabrication, and quality control. These elements combined increase JEB’s international appeal, allowing its wall systems to be at their best anywhere, and for any project.

Product Design

Quality of construction starts within the very essence of design, and the way a product is designed. JEB’s latest partition system ‘Summit’ is testament to this way of thinking. The system is made up of less individual extrusions than previous partitions in the JEB range – meaning there are fewer materials to fabricate, freight, deliver to site, unpack, and of course, construct once on site. The unique glazing system also provides ample tolerance for the installation of glass, allowing all joints to be as neat as possible.

Tailored Design

A part of JEB’s greatest appeal is the ability to work directly with the client to meet individual project needs. Every project is unique, and JEB is committed to understanding the nuances of each workspace and even the greater brand message of the company.

This can mean creating new extrusions for an individual client – JEB’s design and product team uses advanced tools and technology like 3D printers to speed up design and testing (link to previous article on JEB 3D printers). This means clients can see prototypes in early stages, and make more informed stylistic and functional decisions from the outset.

For instance, At Allen & Overy’s new fit out in Thailand, Orbit Design; saw an opportunity to take our Brooklyn system one step further by designing their own transoms and mullions to suit their design style. We provide designers the opportunity to design, rather than settling for generic off the shelf building materials.

Prefabrication

By sending ready made, prefabricated materials to site – pre machined, cut and finished – this cuts down assembly time, minimizes mistakes and minimizes defects. The aim for this process is to reduce the on-site skill required for installation, and for the system to be installed, and perform perfectly. From a global perspective, this allows JEB to be more competitively priced in countries that have higher labour costs, and reduce installation time where project schedules are constantly being reduced.

Quality Control

JEB boasts a set of stringent quality control procedures, taken from ISO standards of manufacturing. This means that JEB has been more successful in producing difficult systems such as curved partitions and curved double glazed door leafs. JEB has dedicated Quality Control teams, which means these trickier systems are included as part of the standard range.

JEB International

jebinternational.com

INDESIGN is on instagram

Follow @indesignlive

A searchable and comprehensive guide for specifying leading products and their suppliers

Keep up to date with the latest and greatest from our industry BFF's!

London-based design duo Raw Edges have joined forces with Established & Sons and Tongue & Groove to introduce Wall to Wall – a hand-stained, “living collection” that transforms parquet flooring into a canvas of colour, pattern, and possibility.

A longstanding partnership turns a historic city into a hub for emerging talent

For Aidan Mawhinney, the secret ingredient to Living Edge’s success “comes down to people, product and place.” As the brand celebrates a significant 25-year milestone, it’s that commitment to authentic, sustainable design – and the people behind it all – that continues to anchor its legacy.

QT Perth represents a new level of designer hospitality in the heart of WA. For the final touches, Indyk Architects knew to turn to JEB.

With office partitions being the go-to solution for so much of the working world, the JEB team realised, why settle for bland? Enter the Brooklyn series…

The internet never sleeps! Here's the stuff you might have missed

In the latest collaboration between Designer Rugs and Greg Natale, the raw rigour of modernist geometries finds its most comforting articulation in the inherent softness of floor coverings.

Several design groups are coming together on 29th October, 2025 for ‘grounded,’ a day of talks and workshops on Country-centred design.

CPD Live returns for its final live-presented season of 2025, bringing architects, designers, and specifiers a free opportunity to earn CPD points before the year ends. Kicking off at 9 AM AEDT, This Tuesday 14th October.

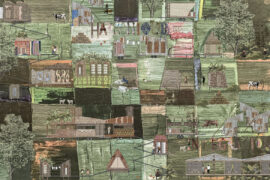

Annabelle Smith has been named winner of The Graduate at the INDE.Awards 2025, in partnership with Colorbond. Her visionary project reimagines housing in Aotearoa, proposing a modular and culturally responsive model uniting people, architecture and nature.